ISO 9001 Implementation Steps for Business Success

Navigate Your ISO 9001 Implementation: QMS & Certification Essentials

Embarking on your ISO 9001 implementation journey involves a structured approach to establishing a robust Quality Management System. This system is designed to elevate efficiency, enhance customer satisfaction, and foster continuous improvement, all while bolstering data integrity and operational resilience. Within this guide, you’ll find clear definitions, fundamental principles, an explanation of the PDCA cycle, the importance of risk-based thinking, seven practical implementation steps, best practices for documentation, integration with IT security, strategies for ongoing maintenance, typical certification timelines, and insights into how Acato’s expert consultancy and training services can accelerate your progress. By diligently following these ISO 9001 implementation steps, businesses of all sizes, from small and medium enterprises to large corporations, can refine their processes, meet stakeholder expectations, and drive sustainable growth.

What is ISO 9001 and How Does it Drive Business Success?

ISO 9001 stands as an internationally recognised standard that outlines the requirements for a comprehensive Quality Management System. It acts as a catalyst for business success by improving process efficiency, elevating customer satisfaction, and promoting continuous improvement through a structured, process-oriented framework. Developed by the International Organization for Standardization, ISO 9001 empowers organisations of any scale to consistently deliver high-quality products and services, while adeptly identifying potential risks and opportunities that align with strategic objectives.

ISO 9001 and Quality Management Systems

ISO 9001 serves as the international benchmark for a robust Quality Management System, driving business success by enhancing process efficiency, customer satisfaction, and continuous improvement through a process-centric framework. Established by the International Organization for Standardization, ISO 9001 assists organisations of all sizes in delivering consistent, high-quality products and services, while also identifying risks and opportunities that support strategic goals.

International Organization for Standardization

This citation clarifies the definition and purpose of ISO 9001, which is fundamental to the article’s introduction.

What Are the Core Principles of ISO 9001:2015?

The 2015 revision of ISO 9001 is built upon seven core principles that guide a Quality Management System towards achieving excellence and maintaining a strong customer focus.

- Customer Focus – Placing customer needs at the forefront to enhance satisfaction.

- Leadership – Ensuring top management establishes a clear unity of purpose and direction.

- Engagement of People – Cultivating competence and active involvement across all organisational levels.

- Process Approach – Managing activities as a series of interconnected processes.

- Improvement – Driving the ongoing enhancement of performance.

- Evidence-Based Decision-Making – Utilising data and analysis to inform actions.

- Relationship Management – Optimising interactions with all relevant interested parties.

These principles form the foundation for every ISO 9001 implementation step, setting the stage for a quality-centric culture that naturally leads to a deeper understanding of the QMS structure.

How Does a Quality Management System (QMS) Support Business Improvement?

A Quality Management System (QMS) provides a structured framework encompassing policies, processes, and procedures that align organisational objectives with customer expectations, minimise variability, and drive continuous improvement. Adopting an ISO 9001 process approach ensures that the interdependencies between various activities are effectively managed, inefficiencies are identified, and outcomes become more predictable—ultimately paving the way for measurable business enhancements and more robust data governance.

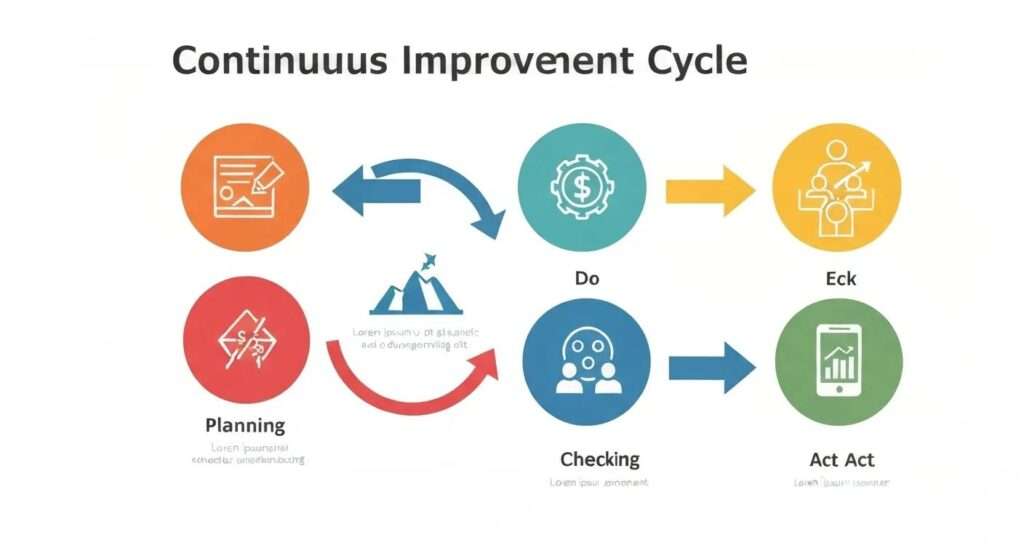

What Is the PDCA Cycle and Why Is It Essential for ISO 9001?

The PDCA Cycle (Plan-Do-Check-Act) serves as the driving force behind continuous improvement within ISO 9001, establishing a repeatable framework that embeds quality into every operational stage.

Before delving into each phase, this table offers a concise summary of PDCA in an EAV (Element, Action, Value) format:

| Stage | Purpose | Key Activities |

|---|---|---|

| Plan | Establish objectives and processes | Define the QMS scope, set quality objectives, and implement risk controls |

| Do | Implement processes | Execute documented procedures, allocate resources, and conduct training |

| Check | Monitor and measure | Perform internal audits, gather performance data, and analyse metrics |

| Act | Improve system | Implement corrective and preventive actions, and update processes |

The PDCA Cycle in ISO 9001

The PDCA Cycle (Plan-Do-Check-Act) is the engine of continuous improvement in ISO 9001, defining a repeatable cycle that embeds quality at every stage of operations. By consistently cycling through PDCA, organisations reinforce learned lessons and continuously enhance process reliability, laying the groundwork for systematic risk management.

Deming, W. Edwards, Out of the Crisis (1982)

This citation underscores the significance of the PDCA cycle, a pivotal concept discussed throughout the article.

By consistently cycling through PDCA, organisations reinforce learned lessons and continuously enhance process reliability, laying the groundwork for systematic risk management.

How Does Risk-Based Thinking Enhance ISO 9001 Implementation?

Risk-based thinking ensures that potential threats and opportunities are proactively identified, analysed, and addressed, rather than reactively managed, thereby strengthening a QMS’s resilience and adaptability.

Risk-Based Thinking in ISO 9001

Risk-based thinking ensures that potential threats and opportunities are identified, analysed, and treated proactively rather than reactively, which strengthens a QMS’s resilience and adaptability. Integrating these risk considerations into each ISO 9001 implementation step creates a dynamic system that evolves alongside organisational and environmental changes.

ISO 9001:2015 Quality management systems — Requirements

This citation explains the crucial role of risk-based thinking, a key element within the ISO 9001 implementation process.

Introducing key risk attributes within the QMS context:

| Risk Element | Parameter | Impact on QMS |

|---|---|---|

| Identification | Threats and opportunities | Guides the implementation of controls and resource allocation |

| Assessment | Likelihood and severity | Helps prioritise risk treatment measures |

| Treatment | Controls and actions | Ensures process reliability and compliance |

Integrating these risk considerations into each ISO 9001 implementation step creates a dynamic system that evolves alongside organisational and environmental changes.

What Are the 7 Key Steps to Implement ISO 9001 Successfully?

The seven critical steps for successfully implementing ISO 9001 include securing leadership commitment, conducting a thorough gap analysis, developing the necessary documentation, integrating and training the team, planning and executing internal audits, holding effective management reviews, and preparing for certification audits while embedding a culture of continuous improvement.

How to Secure Leadership Commitment and Define Your QMS Scope?

Securing commitment from top management ensures that essential resources and strategic direction are readily available, and that the QMS aligns seamlessly with overarching organisational goals. Defining the QMS scope clearly outlines which processes, departments, and geographic locations are included, thereby establishing clear boundaries and interfaces for effective implementation.

How to Conduct a Gap Analysis and Design Your QMS?

A gap analysis involves comparing your current processes against the requirements of ISO 9001 to pinpoint any non-conformities and areas ripe for improvement, forming the foundational blueprint for your system design. By meticulously mapping existing practices against each clause of the standard, teams can effectively prioritise actions and allocate resources to close identified gaps efficiently and sustainably.

What Documentation Is Required and How to Develop It Efficiently?

ISO 9001 certification necessitates the documentation of your quality policy, objectives, scope statement, Quality Manual, relevant procedures, and records. Efficient development is best achieved by leveraging proven templates and tools:

- Quality Manual – Provides an overview of the QMS structure and the interactions between its processes.

- Procedure Templates – Standardise the way processes are described.

- Record Forms – Capture evidence of conformity and performance.

Utilising “ISO 9001 documentation templates” from Acato can significantly accelerate this phase by providing industry-tested forms that ensure both completeness and consistency.

These essential documents form the backbone of your system, enabling transparent tracking of roles, responsibilities, and outcomes.

How to Implement the QMS and Train Your Team Effectively?

Implement the QMS by integrating documented processes into daily operations, assigning clear responsibilities, and deploying a comprehensive training program that covers policy, objectives, procedures, and risk awareness. Engaging staff through interactive workshops and practical, real-world scenarios solidifies competence, encourages ownership, and cultivates a quality-focused culture that reinforces both ISO 9001 principles and effective data management practices.

How to Plan and Conduct Internal Audits for ISO 9001?

Internal audits are crucial for verifying conformity to documented procedures and assessing the overall effectiveness of the QMS. A well-structured audit schedule, auditors who are properly trained, and clearly defined checklists ensure that all processes are systematically covered. Findings from these audits are then used to inform corrective and preventive actions, driving the “Check” and “Act” phases of the PDCA Cycle and reinforcing the commitment to continuous improvement.

What Happens During Management Review and Why Is It Important?

During a management review, senior leaders critically evaluate audit results, performance metrics, the current risk status, and ongoing improvement initiatives to make informed strategic decisions. This vital step confirms that the QMS remains aligned with organisational objectives and external requirements, allowing for necessary adjustments in policy, resource allocation, and risk treatment plans to sustain long-term success.

How to Prepare for Certification Audit and Ensure Continual Improvement?

Preparation for the external certification audit involves finalising all documentation, conducting a comprehensive internal audit of the entire system, and addressing any identified non-conformities. Engaging a third-party auditor will verify compliance and lead to the issuance of your certification. Beyond the audit itself, embedding a culture of continuous improvement ensures that the QMS evolves in line with changing business needs and stakeholder expectations, leveraging lessons learned to drive ongoing excellence through every PDCA cycle and risk management iteration. For detailed insights into the formal “ISO 9001 certification process,” explore Acato’s guide on ISO 9001 certification, which offers actionable audit-readiness checklists.

How Do You Develop and Manage ISO 9001 Documentation and Templates?

Developing and managing documentation effectively ensures consistency, traceability, and control over all recorded information, which is absolutely critical for audit readiness and ongoing improvement. Documented information must be regularly reviewed, updated, and protected against loss or unauthorised changes to maintain the integrity of the QMS.

What Are the Mandatory Documents for ISO 9001 Certification?

- The quality policy and quality objectives.

- The defined scope of the Quality Management System.

- A Quality Manual or its equivalent.

- Documented procedures for the control of records, internal audits, non-conformity, and corrective actions.

- Records pertaining to training, calibration, management reviews, and audit results.

Ensuring these documents are in place and kept current is essential for a successful certification journey and establishes a transparent system of accountability.

How to Create a Quality Manual and Procedure Templates?

A Quality Manual outlines the QMS structure, the interactions between its various processes, and provides references to documented procedures. Procedure templates, in turn, guide the consistent description of processes, responsibilities, and the required records. Using standardised templates minimises ambiguity, speeds up deployment, and supports audit traceability—ultimately reinforcing business efficiency and compliance.

What Are Best Practices for Record Keeping and Document Control?

Effective record keeping involves secure storage, clear identification of retention periods, and controlled disposal methods. Document control practices include implementing version numbering, establishing approval workflows, and enforcing access restrictions. These controls are vital for preserving data integrity, supporting traceability during audits, and ensuring that teams consistently work with the most up-to-date procedures and forms.

How Can You Integrate ISO 9001 with IT Security and Data Management?

Combining quality management principles with robust IT security and data governance ensures that process reliability and information integrity mutually reinforce each other, thereby minimising risks to product quality and sensitive data across the entire value chain.

What Are the Benefits of Combining ISO 9001 with ISO 27001?

An integrated management system that harmonises ISO 9001’s quality principles with ISO 27001’s information security controls offers unified objectives, reduces duplication of effort, streamlines audits, and strengthens customer trust. By aligning risk assessments and controls, organisations can effectively safeguard both product quality and data confidentiality within a single, consistent framework.

How Does ISO 9001 Support Data Protection and GDPR Compliance?

ISO 9001’s emphasis on documented processes, record control, and continuous improvement directly complements GDPR requirements by enforcing clear data-handling procedures, audit trails, and accountability. Embedding privacy controls within the QMS ensures that data subject rights, breach response protocols, and data minimisation practices are managed as integral parts of everyday quality processes.

What Are Practical Steps to Align QMS with IT Security Frameworks?

- Map your quality processes to information security requirements and identify any overlapping controls.

- Integrate risk registers to simultaneously address both quality and security threats.

- Expand your audit programmes to encompass checks for both product/process quality and data protection.

- Train cross-functional teams on combined quality and security objectives.

This strategic alignment fosters a resilient, unified system that effectively protects both product integrity and critical information assets.

How Do You Maintain and Improve Your ISO 9001 Quality Management System?

Sustaining a QMS requires a dedicated focus on continuous improvement, diligent performance measurement, and proactive management of risks and opportunities that impact quality outcomes.

What Is the Role of Continuous Improvement in ISO 9001?

Continuous improvement empowers organisations to refine their processes, eliminate inefficiencies, and adapt to evolving requirements. By effectively leveraging PDCA cycles, insights from audit findings, and performance metrics, teams can implement targeted enhancements that sustain customer satisfaction and drive operational excellence.

How to Use KPIs to Measure QMS Effectiveness?

Key Performance Indicators (KPIs), such as on-time delivery rates, defect rates, customer satisfaction scores, and the number of audit non-conformities, provide quantitative insights into the health of your QMS. Tracking these metrics against established targets helps to highlight trends, uncover the root causes of issues, and inform strategic improvement initiatives.

How to Manage Risks and Opportunities for Long-Term Success?

A proactive risk management process involves identifying potential disruptions, evaluating their impact on quality objectives, and implementing preventive measures. Simultaneously, capitalising on opportunities—such as adopting process automation or forging strategic supplier partnerships—drives innovation and enhances competitive advantage, reinforcing the QMS’s crucial role in achieving sustainable business success.

What Is the ISO 9001 Certification Process and How Long Does It Take?

Achieving ISO 9001 certification involves selecting an accredited certification body, completing the necessary documentation and audits, and typically takes between three to six months, depending on the organisation’s size and the complexity of its system.

How to Choose a UKAS Accredited Certification Body?

Selecting a UKAS-accredited certification body guarantees an impartial and competent assessment that is recognised globally. Organisations should verify the body’s scope of accreditation, its audit approach, and its experience within your industry to ensure a good fit with your Quality Management System.

What Are the Typical Costs and Timelines for ISO 9001 Certification?

Certification costs can vary significantly based on the organisation’s size, scope, and the complexity of its processes, generally ranging from £2,000 to £10,000. Timelines are influenced by the maturity of your system and the availability of resources; initial certification audits are often completed within two to four days, following thorough gap analyses and internal audits that prepare the organisation.

How to Prepare for the Certification Audit Successfully?

Preparation involves finalising all documentation, conducting comprehensive internal audits across the entire system, addressing any identified non-conformities, and arranging pre-audit reviews. Clearly defined roles and responsibilities, along with evidence of continuous improvement, will reassure auditors and pave the way for a smooth certification decision.

How Can Acato Support Your ISO 9001 Implementation Journey?

Acato brings extensive expertise in IT security and data management to guide you through every phase of your ISO 9001 implementation, ensuring that quality and information integrity advance hand in hand.

What Consultancy Services Does Acato Offer for ISO 9001?

Acato’s consultancy services encompass gap analysis, QMS design, documentation development, internal audit support, and certification audit preparation, all meticulously tailored to your industry-specific requirements and compliance context.

How Does Acato’s Training Program Enhance Your Team’s Readiness?

Through interactive workshops, role-specific training modules, and scenario-based exercises, Acato equips your team with the essential knowledge and skills to confidently operate the QMS, reinforcing a strong quality culture and aligning data management practices with ISO requirements.

What Are Real Success Stories from Acato’s Clients?

A UK-based law firm successfully improved document traceability by 40% and significantly strengthened its GDPR compliance through the integration of quality and security controls. A mid-sized manufacturer achieved a 25% reduction in defect rates within just six months of implementing its QMS. These tangible outcomes clearly demonstrate how Acato’s integrated approach delivers measurable business success.

Partner with Acato to streamline your ISO 9001 implementation steps, fortify your data security, and transform your Quality Management System into a strategic asset that drives customer trust, operational excellence, and sustainable growth.